Photochemical Karfe Etching

Yin Amfani da Tsarin Taimakon Kwamfuta (CAD)

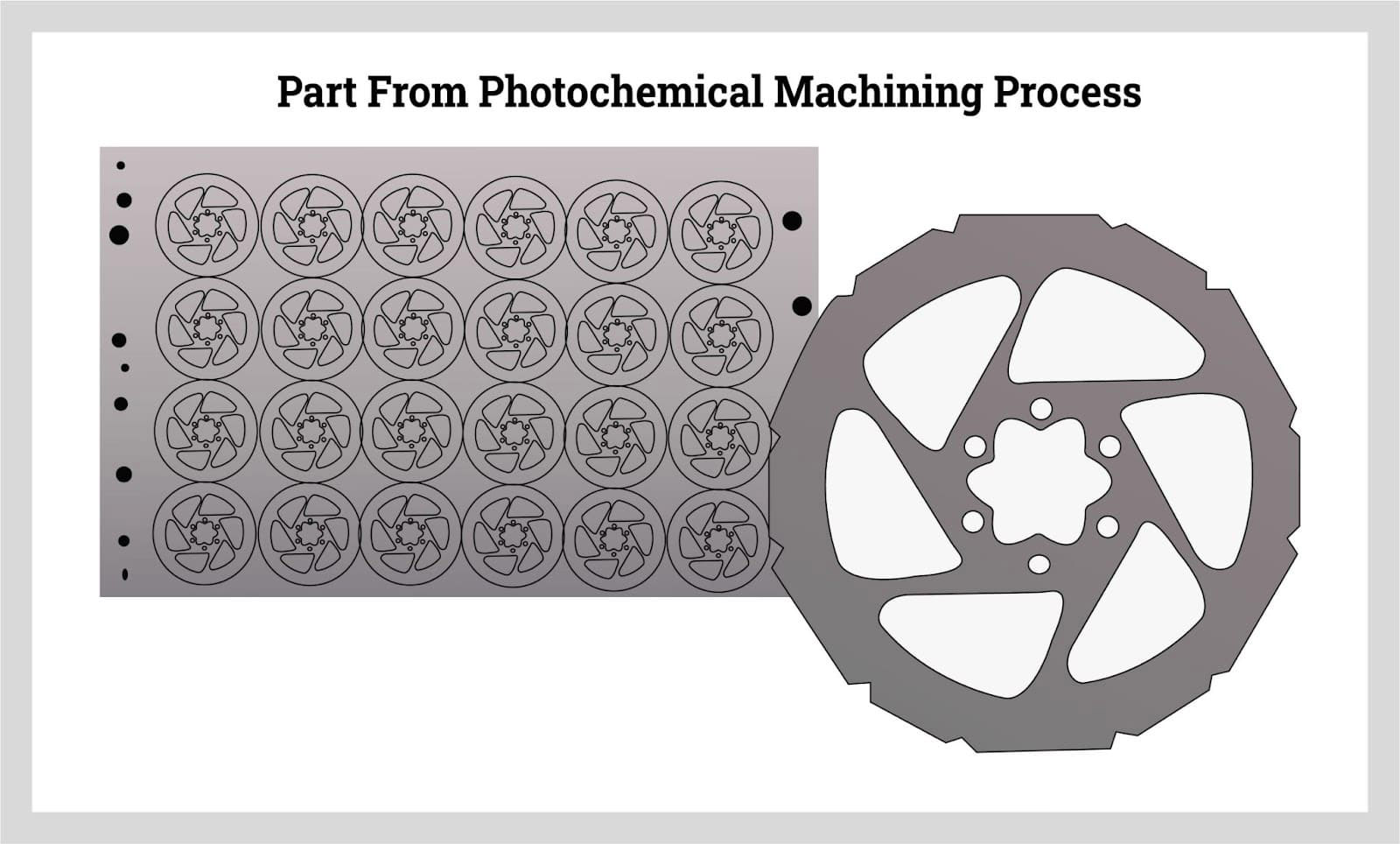

Tsarin etching karfe na photochemical yana farawa tare da ƙirƙirar ƙira ta amfani da CAD ko Adobe Illustrator.Kodayake zane shine mataki na farko a cikin tsari, ba shine ƙarshen lissafin kwamfuta ba.Da zarar an gama ƙaddamarwa, an ƙayyade kauri na ƙarfe da kuma adadin adadin da za su dace a kan takarda, wani abu mai mahimmanci don rage farashin samarwa.Bangare na biyu na kauri na takardar shine ƙayyadaddun juzu'in juzu'i, wanda ke rataye akan girman ɓangaren.

Tsarin etching karfe na photochemical yana farawa tare da ƙirƙirar ƙira ta amfani da CAD ko Adobe Illustrator.Koyaya, ba wannan ba shine lissafin kwamfuta kaɗai ba.Bayan kammala zane, an ƙayyade kauri na karfe, da kuma adadin adadin da za su iya dacewa a kan takarda don rage farashin samarwa.Bugu da ƙari, jurewar ɓangaren ya dogara da girman ɓangaren, wanda kuma ya shiga cikin kauri na takardar.

Karfe Shiri

Kamar yadda yake tare da etching acid, dole ne a tsaftace karfe sosai kafin a sarrafa shi.Ana goge kowane yanki na ƙarfe, tsaftacewa, da tsaftacewa ta amfani da matsa lamba na ruwa da ƙaushi mai laushi.Tsarin yana kawar da mai, gurɓatawa, da ƙananan ƙwayoyin cuta.Wannan wajibi ne don samar da tsaftataccen wuri mai santsi don aikace-aikacen fim ɗin photoresist don amintacce.

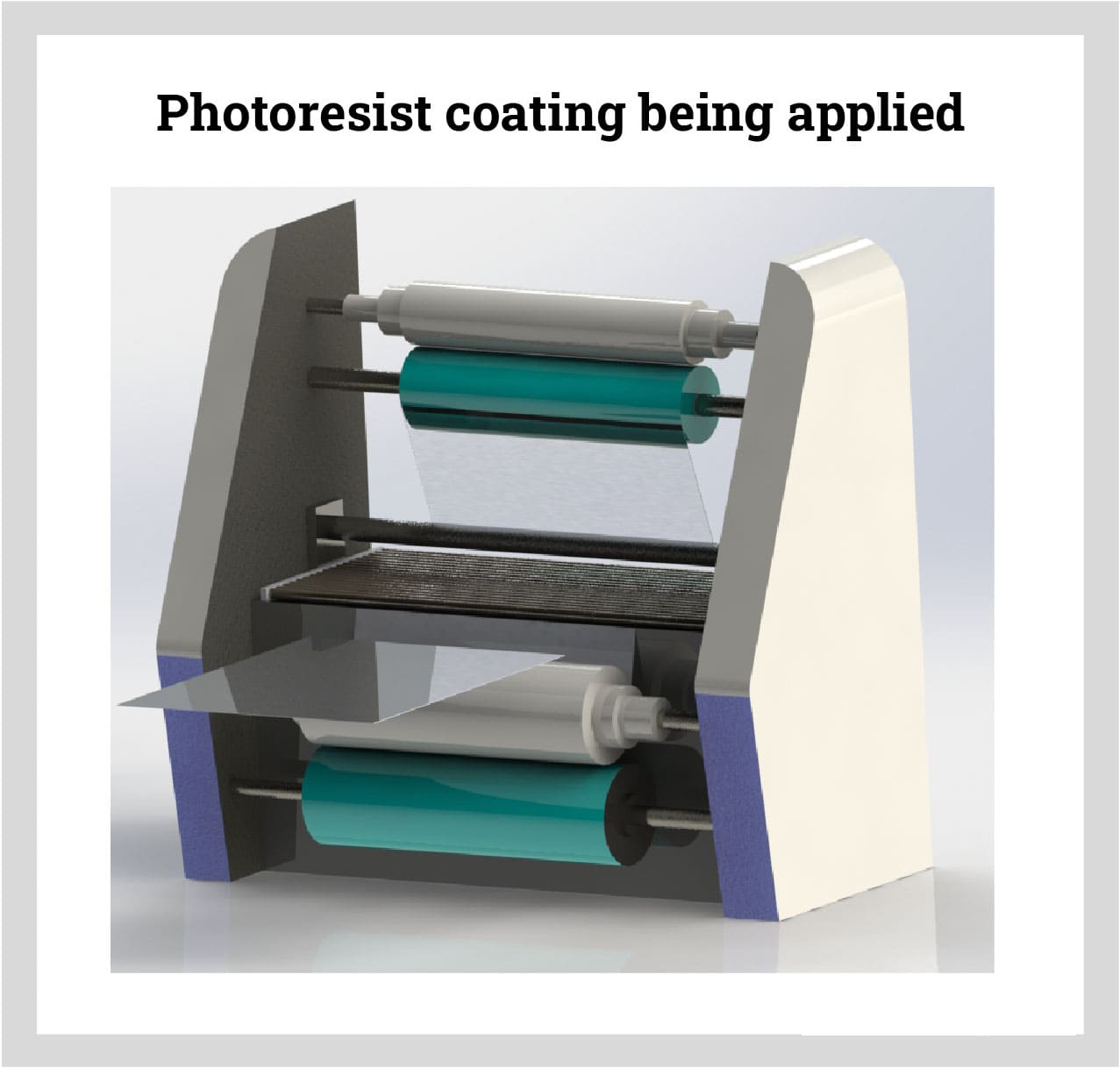

Laminating Metal Sheets tare da Fina-Finan masu ƙin ɗaukar hoto

Lamination shine aikace-aikacen fim ɗin hoto.Ana matsar da zanen ƙarfe a tsakanin rollers waɗanda ke yin sutura kuma suna yin amfani da lamination daidai.Don kauce wa duk wani bayyanar da bai dace ba na zanen gado, ana kammala aikin a cikin ɗaki mai haske tare da hasken rawaya don hana hasken UV.Daidaitaccen jeri na zanen gado yana bayar da ramukan da aka buga a gefuna na zanen gado.Ana hana kumfa a cikin abin da aka lakafta ta hanyar vacuum sealing zanen gado, wanda ke karkatar da yadudduka na laminate.

Don shirya karfe don etching karfe na photochemical, dole ne a tsaftace shi sosai don cire mai, gurɓataccen abu, da barbashi.Kowane yanki na ƙarfe yana gogewa, tsaftacewa, kuma an wanke shi tare da ƙamshi mai laushi da matsa lamba na ruwa don tabbatar da tsaftataccen wuri mai tsabta don aikace-aikacen fim ɗin photoresist.

Mataki na gaba shine lamination, wanda ya haɗa da yin amfani da fim din photoresist zuwa zanen karfe.Ana matsar da zanen gado tsakanin rollers don yin sutura daidai da amfani da fim ɗin.Ana aiwatar da tsarin ne a cikin ɗaki mai haske mai rawaya don hana hasken UV.Ramukan da aka buga a gefuna na zanen gadon suna ba da jeri mai kyau, yayin da ƙugiya mai ƙyalli yana daidaita shimfidar laminate kuma yana hana kumfa daga kafa.

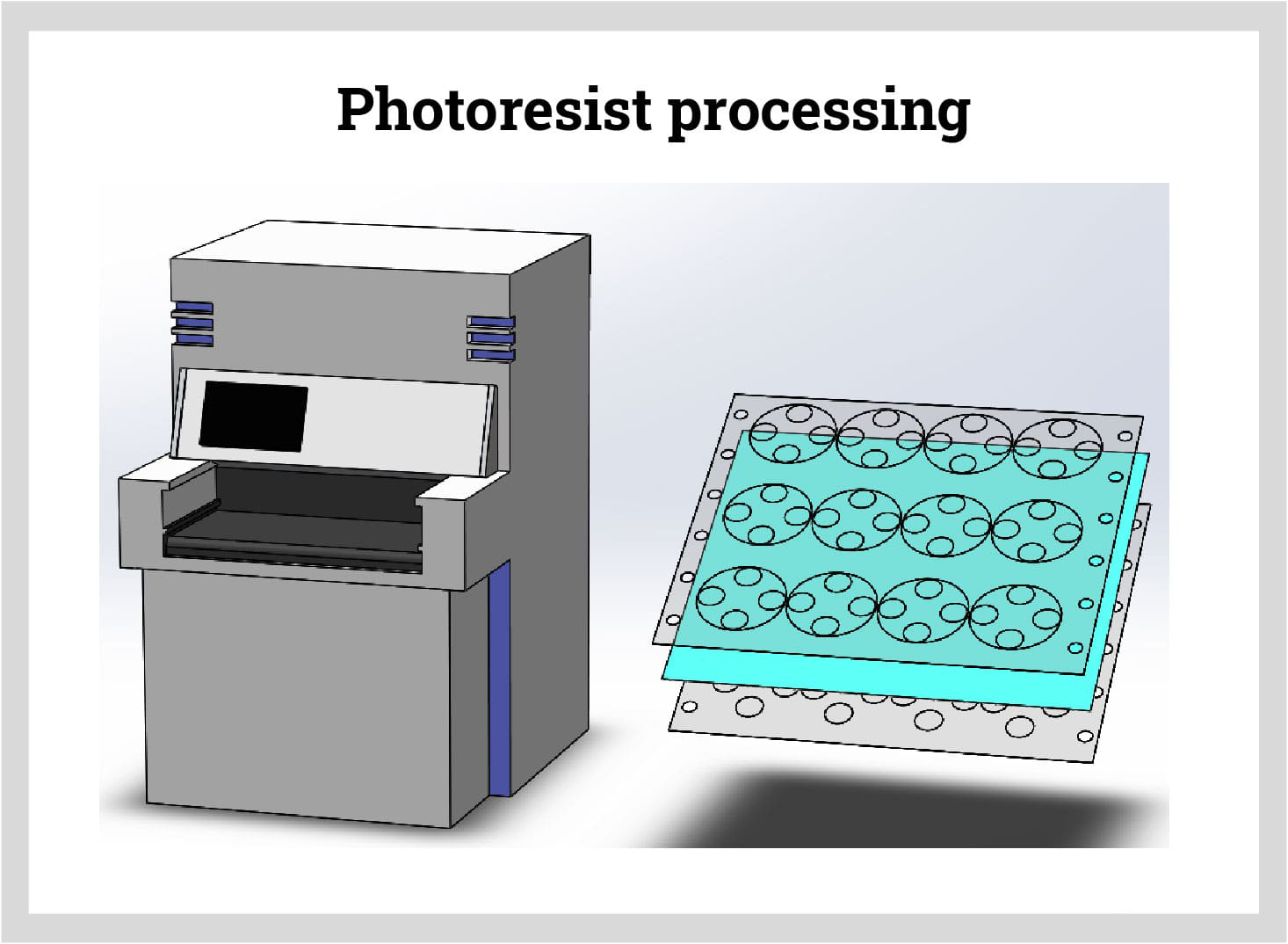

Gudanar da Photoresist

Lokacin sarrafa hoto, hotuna daga CAD ko Adobe Illustrator ana sanya su a kan Layer na photoresist akan takardar ƙarfe.Ana buga ma'anar CAD ko Adobe Illustrator a ɓangarorin biyu na takardar ƙarfe ta hanyar yin sandwiching sama da ƙarƙashin ƙarfen.Da zarar zanen gadon karfe sun yi amfani da hotunan, ana fallasa su zuwa hasken UV wanda ke sanya hotunan dindindin.Inda hasken UV ke haskakawa ta wurin bayyanannun wuraren laminate, mai ɗaukar hoto ya zama mai ƙarfi kuma yana taurare.Yankunan baƙar fata na laminate sun kasance masu laushi kuma basu da tasiri ta hasken UV.

A cikin matakin sarrafa hoto na photochemical karfe etching, hotuna daga CAD ko Adobe Illustrator ana canza su zuwa saman Layer na photoresist akan takardar karfe.Ana yin wannan ta hanyar yin sandwiching da ƙira sama da ƙarƙashin takardar ƙarfe.Da zarar an yi amfani da hotunan a kan takardar ƙarfe, an fallasa shi zuwa hasken UV, wanda ke sa hotuna su zama dindindin.

A lokacin bayyanar UV, wurare masu tsabta na laminate suna ba da damar hasken UV ya wuce, yana sa mai ɗaukar hoto ya taurare kuma ya zama mai ƙarfi.Sabanin haka, wuraren baƙar fata na laminate sun kasance masu laushi kuma ba su da tasiri daga hasken UV.Wannan tsari yana haifar da tsari wanda zai jagoranci tsarin etching, inda wuraren da suka taurare za su kasance kuma za a kawar da wurare masu laushi.

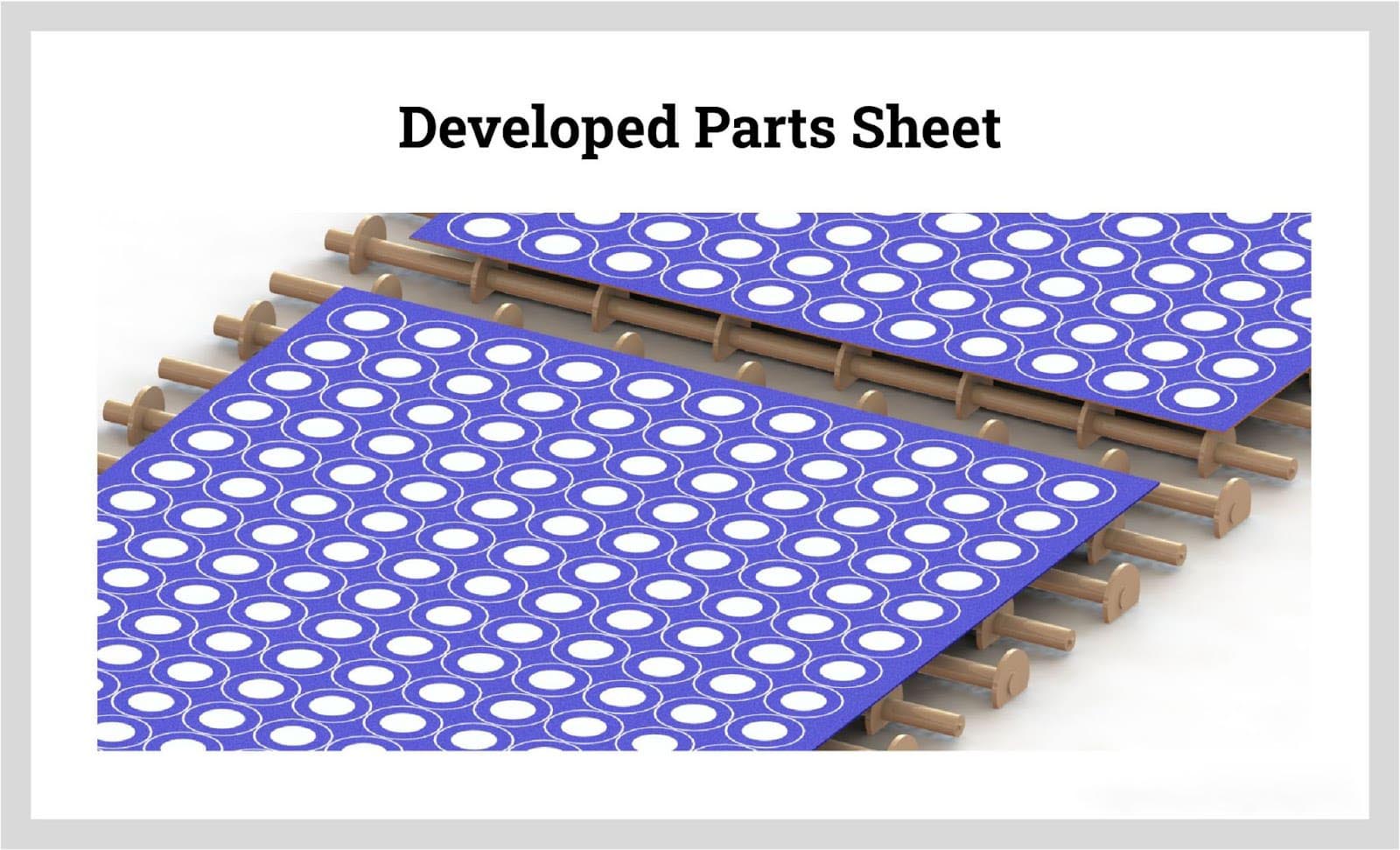

Haɓaka Sheets

Daga aikin sarrafa hoto, zanen gadon suna matsawa zuwa injin haɓakawa wanda ke amfani da maganin alkali, galibin sodium ko potassium carbonate mafita, wanda ke wanke fim ɗin hoto mai laushi yana barin sassan da za a fallasa su.Tsarin yana kawar da juriya mai laushi kuma ya bar juriya mai tauri, wanda shine ɓangaren da za a yi.A cikin hoton da ke ƙasa, wuraren da aka taurare suna cikin shuɗi, kuma wurare masu laushi suna launin toka.Wuraren da ba a kiyaye su ta hanyar laminate mai tauri ba an fallasa su da ƙarfe waɗanda za a cire yayin etching.

Bayan matakin sarrafa photoresist, sai a mayar da zanen karfen zuwa na'ura mai tasowa inda ake amfani da maganin alkali, yawanci sodium ko potassium carbonate.Wannan bayani yana wanke fim ɗin hoto mai laushi mai laushi, yana barin sassan da ake buƙata a ɓoye.

A sakamakon haka, an cire juriya mai laushi, yayin da tsayayyar taurin kai, wanda ya dace da wuraren da ake bukata, an bar shi a baya.A cikin samfurin da aka samu, ana nuna wuraren da aka taurara a cikin shuɗi, kuma wurare masu laushi suna launin toka.Wuraren da ba a kiyaye su ta hanyar tsayayyar taurin suna wakiltar ƙarfe da aka fallasa da za a cire yayin aikin etching.

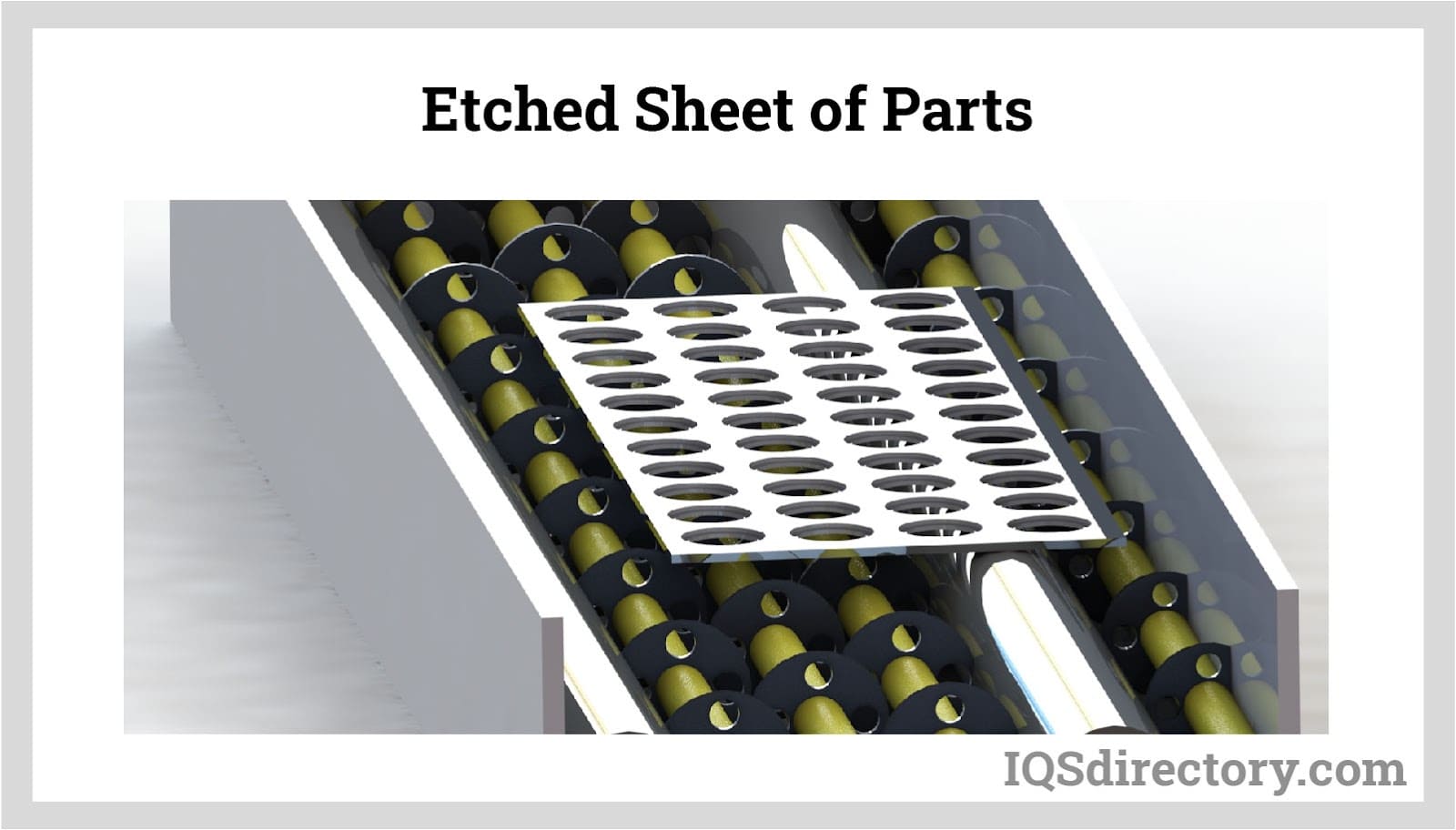

Etching

Kamar tsarin etching na acid, ana sanya zanen gadon da aka haɓaka akan na'ura mai ɗaukar hoto wanda ke motsa zanen gado ta na'urar da ke zub da kaya a kan zanen gado.Inda echant ɗin ya haɗu da ƙarfe da aka fallasa, yana narkar da ƙarfe yana barin kayan kariya.

A mafi yawan hanyoyin sarrafa hoto, abin da ake amfani da shi shine ferric chloride, wanda aka fesa daga ƙasa da saman na'urar.An zaɓi ferric chloride a matsayin abin da ake amfani da shi saboda yana da aminci don amfani kuma ana iya sake yin amfani da shi.Cupric chloride ana amfani dashi don cire jan karfe da kayan haɗin gwiwa.

Dole ne a tsara tsarin etching ɗin a hankali kuma a sarrafa shi daidai da ƙarfen da ake yi tun lokacin da wasu karafa ke ɗaukar tsayin daka fiye da sauran.Don nasarar etching photochemical, kulawa da kulawa da hankali yana da mahimmanci.

A cikin matakin etching na ƙarfe na ƙarfe na photochemical, ana sanya zanen ƙarfe da aka haɓaka akan na'ura mai ɗaukar hoto wanda ke motsa su ta cikin injin inda aka zubar da sauran a jikin zanen gado.Ecchant yana narkar da ƙarfe da aka fallasa, yana barin bayan wuraren kariya na takardar.

Ferric chloride yawanci ana amfani dashi azaman mai ɗorewa a yawancin hanyoyin sarrafa hoto saboda yana da aminci don amfani kuma ana iya sake yin fa'ida.Don jan ƙarfe da kayan haɗin sa, ana amfani da chloride cupric maimakon.

Dole ne a tsara tsarin etching a hankali kuma a sarrafa shi gwargwadon irin nau'in karfen da ake yi, saboda wasu karafa na buƙatar lokaci mai tsayi fiye da sauran.Don tabbatar da nasarar aikin etching photochemical, kulawa da kulawa da hankali yana da mahimmanci.

Cire Fim ɗin Remaing Resistist

A yayin aiwatar da tsigewar, ana amfani da ƙwanƙolin juriya a kan guntuwar don cire duk wani fim ɗin juriya da ya rage.Da zarar an gama cirewa, an bar sashin da aka gama, wanda za'a iya gani a hoton da ke ƙasa.

Bayan aikin etching, sauran fim ɗin tsayayyar da ke kan takardar ƙarfe an cire shi ta hanyar yin amfani da mai juriya.Wannan tsari yana cire duk wani fim ɗin juriya da ya rage daga saman takardar ƙarfe.

Da zarar an kammala aikin cirewa, an bar ɓangaren ƙarfe da aka gama, wanda za'a iya gani a cikin hoton da aka samu.